Initial Need:

The goal of this project was to construct a specialized cold storage facility for fresh lettuce in Shushtar. Lettuce storage is one of the most challenging refrigeration processes, as the product is highly sensitive to minor temperature and humidity fluctuations.

- Excessive cooling can cause freezing and tissue damage in the leaves.

- Temperature increases or humidity drops lead to wilting and quality deterioration.

Thus, the system needed to provide precise and stable control of temperature and humidity within a very narrow range.

Solution:

To meet this specific requirement, our team designed and implemented the refrigeration system using cylinder-piston compressors and R134a refrigerant.

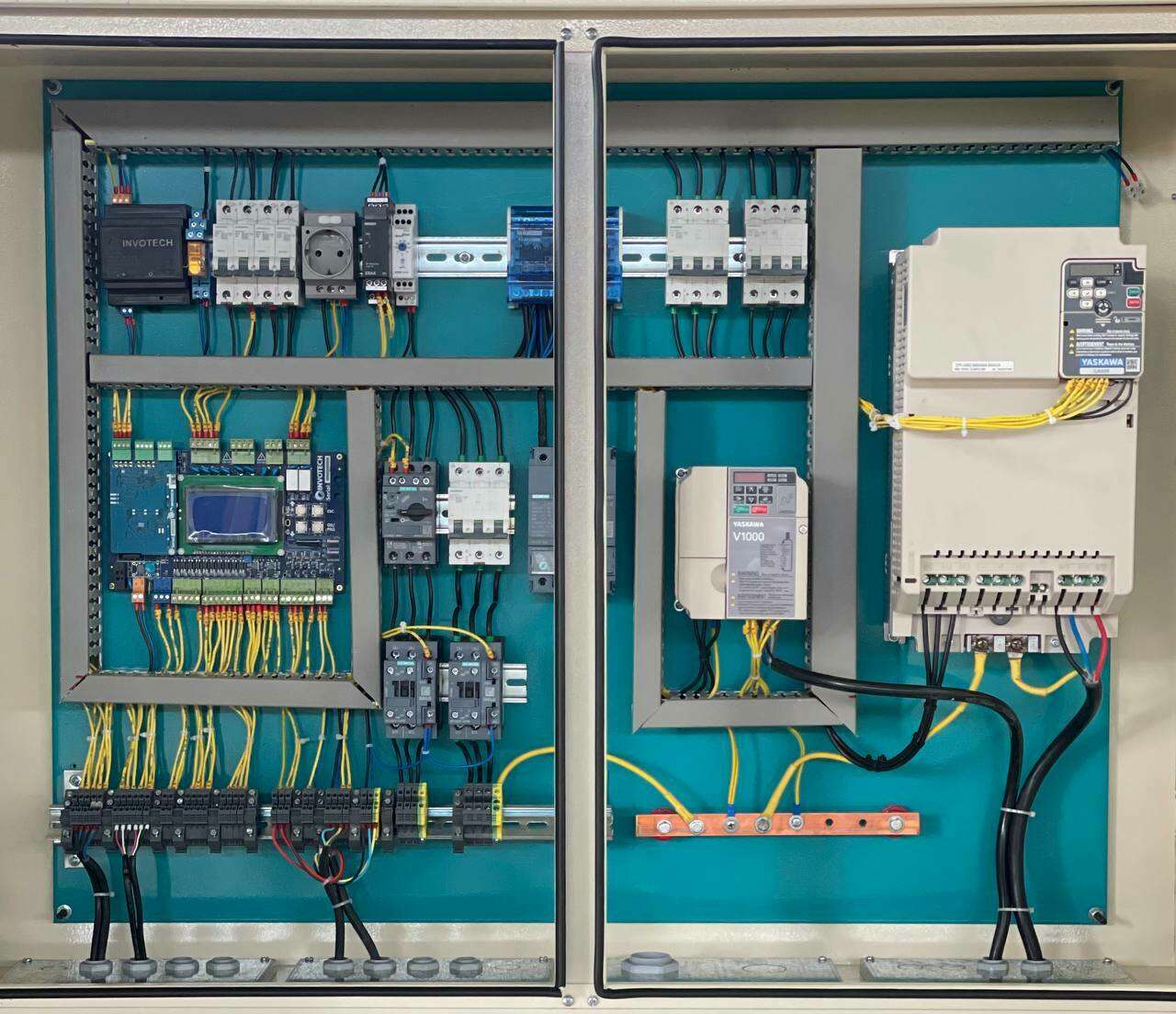

Both cold storage units were designed as full inverter systems, meaning that both compressors and fans are controlled by separate inverters, allowing continuous and precise adjustment of cooling capacity and airflow.

The central control system was implemented using custom-made domestic control boards, enabling real-time adjustment, monitoring, and regulation of temperature and humidity.

Result:

The cold storage facility was successfully commissioned and put into operation, providing stable temperature and humidity conditions for lettuce storage.

The smooth and precise system performance has improved product shelf life and resulted in complete client satisfaction.