Liquid cooling in data center applications is not a new concept. It dates back to the 1960s when it was used in IBM mainframes to address cooling challenges for solid-state devices that were densely packed and had lower allowable operating temperatures. However, the introduction of complementary metal-oxide-semiconductor (CMOS) technology in the early 1990s replaced bipolar semiconductor technology and reduced power consumption. As a result, convective air cooling re-emerged as the default cooling option for IT equipment.

While convective air cooling remains dominant in data centers, the adoption of liquid cooling has become more widespread in video gaming, cryptocurrency mining, and high-performance computing (HPC) applications, which require higher computational capacity with specialized servers.

Liquid cooling is still not widely adopted in the data center industry, primarily because computing demand has been met by increasing the number of logical cores while staying within reasonable power limits. Furthermore, the data center industry tends to be conservative, and new technologies and architectures typically face slow adoption rates.

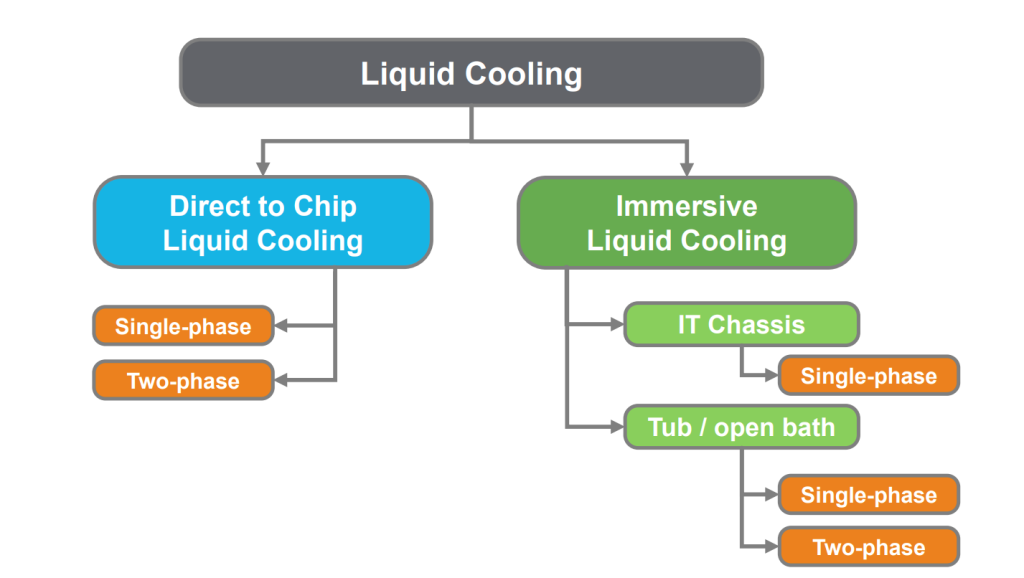

There are two main categories of liquid cooling: Direct-to-Chip (sometimes referred to as cold plate cooling) and Immersion Cooling. From these two categories, a total of five primary liquid cooling methods are derived, as shown in Figure 1.

Direct to chip liquid cooling – single-phase

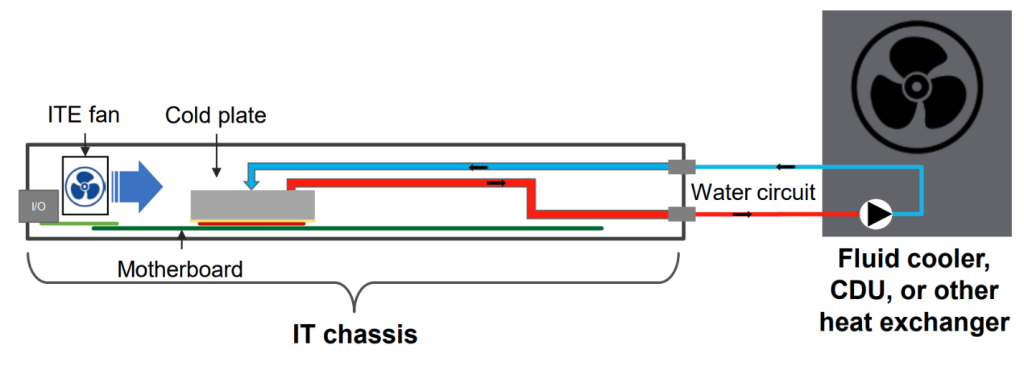

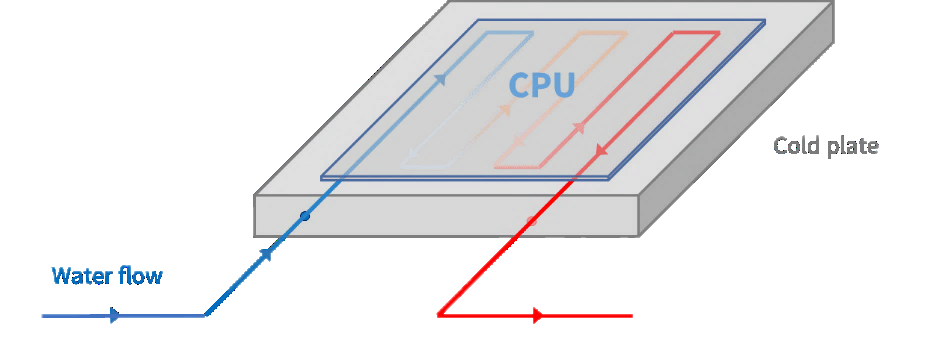

In the direct-to-chip method, the coolant is delivered directly to the hotter components (such as CPUs or GPUs) via a cold plate mounted on the chip inside the server. The IT electronic components do not come into direct physical contact with the coolant (Figure 2). Some designs also include cold plates around memory modules. In this method, fans are still required to provide airflow across the server to remove residual heat. This means that traditional air cooling infrastructure is reduced but still necessary.

Water or dielectric fluids can be used as the coolant for cold plates. The use of water poses a risk of system shutdown in the event of a leak; however, solutions such as Leak Prevention Systems (LPS) are available.

Single-phase means that the fluid does not change its physical state while removing heat. In direct-to-chip cooling, single-phase water-based coolants are primarily used, though some designs also employ engineered dielectric fluids.

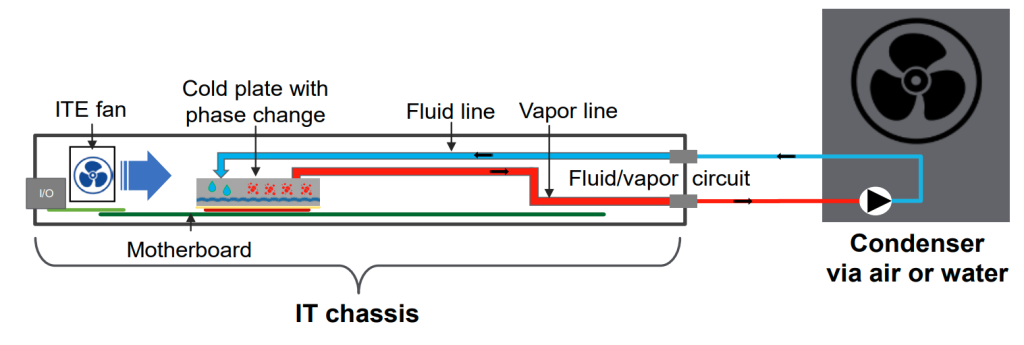

Direct to chip liquid cooling – two-phase

This method is similar to the previous one, with the difference that the fluid is two-phase, meaning the fluid changes from one state to another — specifically, from liquid to gas during the heat removal process. Two-phase cooling is more effective at heat removal compared to single-phase, but it requires additional system controls to ensure proper operation. For two-phase direct-to-chip liquid cooling, engineered dielectric fluids are used. This eliminates the risk of water contact with IT equipment. The dielectric vapor can be transferred to an external condenser to dissipate its heat (Figure 4).

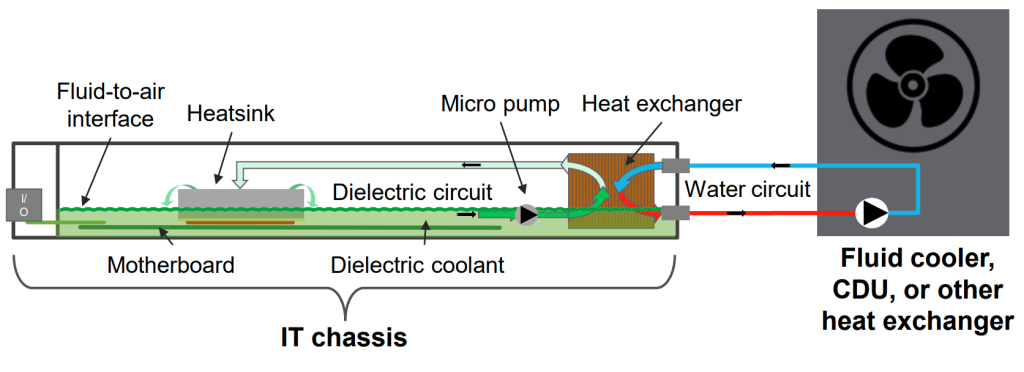

Immersive liquid cooling – IT chassis – single-phase

In immersion liquid cooling, the coolant is in direct physical contact with the IT electronic components. Servers are fully or partially submerged in a dielectric cooling liquid that covers the board and components, ensuring that all heat sources are removed. This method uses single-phase dielectric fluids. In immersion liquid cooling systems, it is possible to eliminate all fans in the server. In this approach, the electronic components are placed in an environment that reacts slowly to external temperature changes, thereby protecting them from humidity and contaminants. Additionally, the absence of fans results in an almost silent operation of the system.

Figure 5 illustrates the single-phase IT chassis approach in immersion liquid cooling systems. In this method, the server is placed inside a sealed chassis and can be deployed as a standard rack-mount IT unit or as standalone equipment. The electronic components are cooled by the dielectric fluid, which can operate passively through conduction and natural convection or actively via forced convection, or even a combination of both. Furthermore, heat exchangers and pumps can be located inside the server or in a side configuration, transferring heat from the dielectric fluid to the chilled water loop.

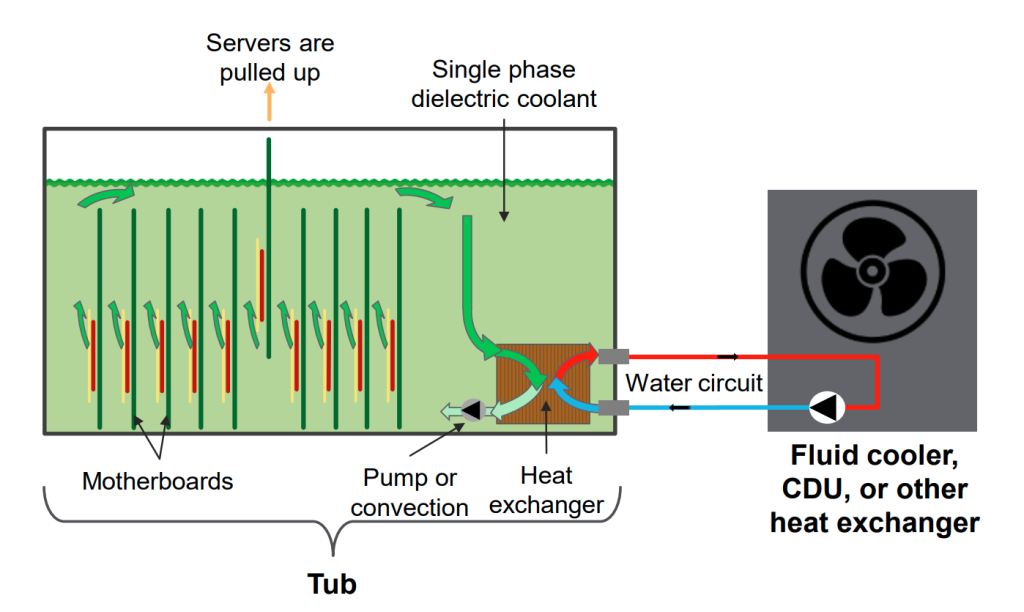

Immersive liquid cooling – Tub – single-phase

In the tank method (also called an open bath), IT equipment is fully submerged in the cooling fluid. In traditional IT racks, servers are arranged horizontally from bottom to top within a rack. However, due to the use of a tank, this method is similar to placing a traditional rack of servers on its side. Instead of removing servers on a horizontal plane, tank immersion servers are pulled out on a vertical plane.

In many cases, this method includes centralized power supplies to provide electricity to all servers within the tank. The heat in the dielectric fluid is transferred to a chilled water loop via a heat exchanger, using either a pump or natural convection. This method typically uses oil-based dielectric fluids. The heat exchanger may be installed either inside or outside the tank.

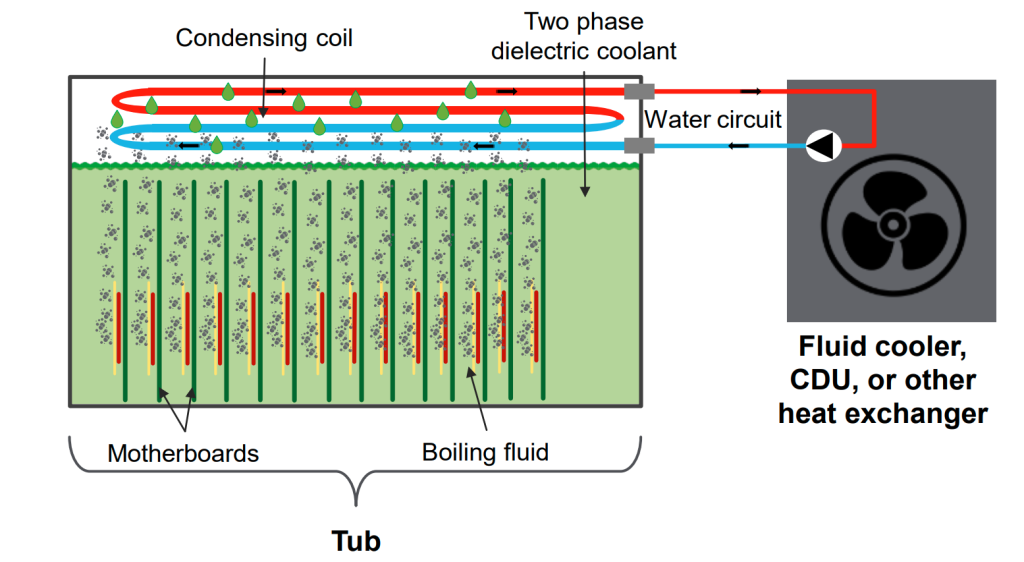

Immersive liquid cooling – Tub – two-phase

Just like the single-phase tank method, the IT equipment is fully submerged in the fluid. The difference here is the use of a two-phase dielectric cooling fluid. Again, this means that the fluid changes from one state to another during heat removal — specifically from liquid to gas. Due to the phase change involved, this fluid must be engineered.

No comments yet.