بA cooling tower is one of the most important industrial and building systems used to remove excess heat from water or process fluids by transferring it to the atmosphere. In many industries—such as power plants, refineries, commercial complexes, and data centers—large volumes of water are used for cooling machinery and HVAC systems. During operation, this water becomes hot, and if it is returned to the system without cooling, equipment efficiency drops significantly. The cooling tower lowers the water temperature close to ambient conditions, allowing it to be reused, thus saving both fresh water and energy.

Operating Principle

The cooling process in a tower is based on evaporative cooling. During this process, a small portion of circulating water evaporates when it comes into contact with incoming air. To change from liquid to vapor, water absorbs latent heat of vaporization from its surroundings—specifically, from the remaining water—causing the bulk water temperature to drop.

The lower the air’s relative humidity and the stronger the airflow, the greater the evaporation and cooling capacity. Because of this, cooling towers can reduce hot water temperature to near the ambient wet-bulb temperature, achieving effective cooling with minimal energy consumption.

Main Components of a Cooling Tower

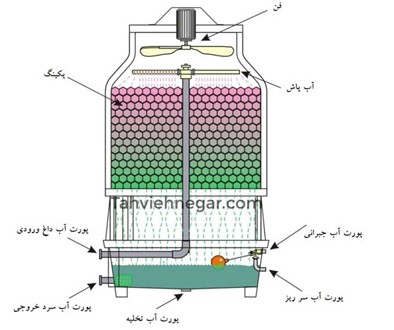

A standard cooling tower consists of several key parts:

- Casing or Structure: Usually made of fiberglass, galvanized steel, or concrete; provides mechanical strength.

- Fan or Propeller: Generates airflow for evaporation and heat dissipation.

- Fill Media (Packing): Increases the contact surface area between air and water for better heat transfer.

- Nozzles & Water Distribution System: Evenly sprays hot water over the fill media.

- Basin: Collects the cooled water for recirculation into the process.

- Air Inlet Louvers & Drift Eliminators: Control the entry of fresh air and prevent water droplets from escaping into the environment.

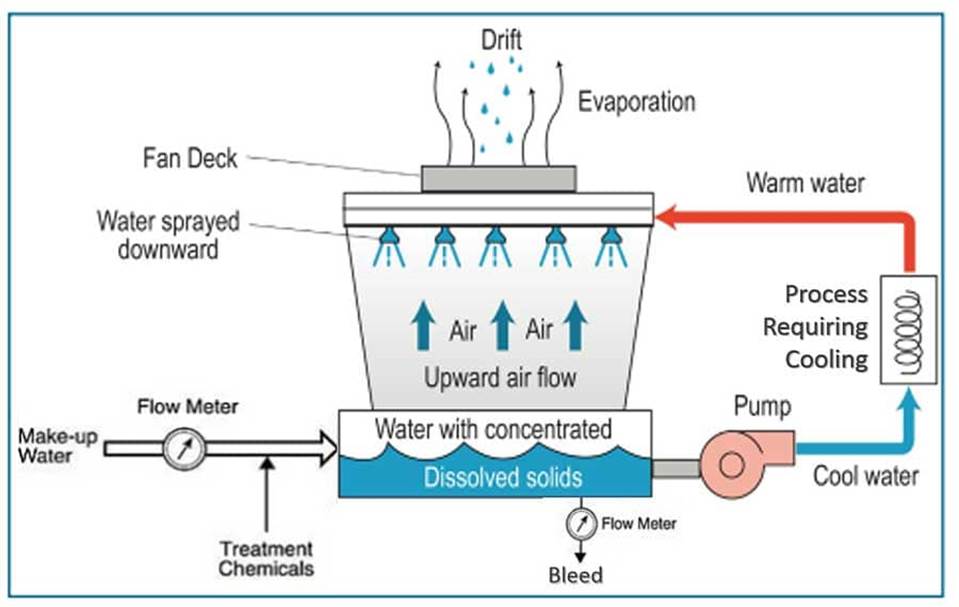

Cooling Tower Cycle

- Hot Water Inlet:

Heated water from chillers, HVAC systems, or industrial processes is pumped to the top of the tower. - Water Distribution:

Nozzles spray water as fine droplets or thin films over the fill media to maximize contact area. - Airflow:

Simultaneously, a fan or natural draft draws air upward (or sideways) through the tower, allowing air and water to mix. - Evaporation & Heat Rejection:

A portion of the water evaporates, absorbing heat (latent heat of vaporization) from the remaining water and lowering its temperature. - Cooled Water Collection:

The cooled water accumulates in the basin at the tower’s bottom and is pumped back into the system.

Types of Cooling Towers

1. Open-Circuit (Wet) Cooling Tower

Hot water is sprayed directly over the fill and comes into contact with air. Part of the water evaporates, removing heat. This type is the simplest and most economical for most industrial applications but requires careful water quality management to prevent scaling and fouling.

2. Closed-Circuit Cooling Tower

The process fluid flows inside a sealed coil and transfers heat to the surrounding spray water or air. Since the process fluid doesn’t contact air, contamination, scaling, and evaporation are minimized—ideal for sensitive applications such as food, pharmaceutical, and electronics industries.

3. Hybrid Cooling Tower

Combines features of both open and closed systems. In cool weather, it operates in dry mode to minimize water consumption; in hot weather, it switches to wet mode for maximum cooling. Hybrid designs offer high efficiency and reduced visible vapor plumes.

Based on Airflow Direction

- Induced Draft Tower:

The fan is mounted at the top, pulling air upward through the tower. Provides efficient airflow, quiet operation, and is widely used in large plants and power stations. - Forced Draft Tower:

The fan is located at the air inlet, pushing air into the tower. Suitable for compact installations or horizontal layouts. Easier to maintain but generally noisier due to fan placement.

Applications

Cooling towers are widely used in:

- Thermal power plants

- Oil refineries and petrochemical facilities

- Steel and metal industries

- Food and pharmaceutical manufacturing

- Central HVAC systems

- Data centers and commercial complexes

These systems not only save water but also reduce energy consumption and maintenance costs across cooling operations.

No comments yet.